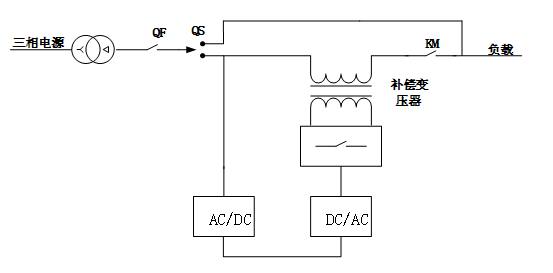

1、Working principle

The automatic voltage regulator is composed of an AC-DC-AC converter, a knife switch QS, a circuit breaker QF, a contactor KM, and a compensation transformer. The AC-DC-AC converter adopts fully controlled power electronic devices, which can achieve bidirectional energy flow. The knife switch QS is switched to the bypass state during maintenance. The contactor KM is used to disconnect or connect the load in the compensation state. The automatic voltage regulator monitors whether the grid voltage deviates from the set value in real time by sampling the grid voltage. Once it deviates from the set value, it controls the AC-DC-AC converter to output the voltage with the same or opposite polarity to the grid voltage, regulates the voltage amplitude and polarity of the compensation transformer in series in the main circuit, and ensures the stability of the load terminal voltage.

2、Performance characteristics

Ø Adopting new power electronics technology, voltage stepless regulation, high regulation accuracy, and no flicker during the regulation process.

Ø The power part of the converter adopts LCL filtering method, which has good filtering effect and no high-frequency harmonic injection load in the output, without interference to other systems and equipment.

Ø The compensation voltage can be adjusted according to user requirements, and the voltage adjustment speed can be set. The output voltage can be independently adjusted using split phase control to adapt to severe unbalanced loads.

Ø The inverter adopts a modular design, which is easy to maintain and has good scalability.

Ø Equipped with overload protection, software/hardware overcurrent protection, power grid overvoltage/undervoltage protection, over temperature protection, frequency anomaly protection, etc., to improve the reliability of power supply.

Ø Equipped with current limiting output function, it can continuously and effectively compensate without exiting operation due to overload.

Ø It has fault alarm and memory functions, and can store fault records for 30 fault days within the storage range, with no limit to the number of records.

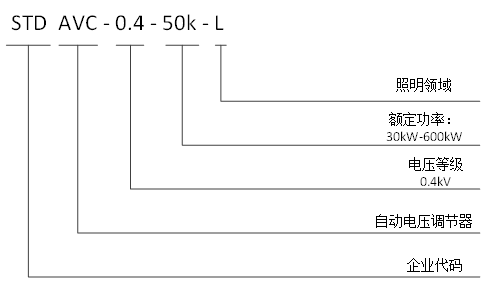

3、Model and appearance

Model Description

Automatic voltage regulator

4、Technical parameters

|

Project |

Single phase 220 series |

Three phase 380V series |

|

|

Altitude |

≤1500m |

≤1500m |

|

|

Ambient temperature |

-20~+50℃ |

-20~+50℃ |

|

|

Relative humidity |

≤90%,月平均最低温度25℃表面无凝露 |

≤ 90%, with a monthly average minimum temperature of 25 ℃ and no condensation on the surface |

|

|

Pollution level |

Below Level III |

Below Level III |

|

|

Working voltage |

AC220V(-20%~+20%) |

AC380V(-20%~+20%) |

|

|

Working frequency |

50Hz±5% |

50Hz±5% |

|

|

Output |

Output voltage |

220V±1% |

220V±1% |

|

Voltage regulation method |

Pole less , contactless |

Pole less , contactless |

|

|

Adjustment method |

Split phase regulation |

Split phase regulation |

|

|

Harmonic voltage distortion rate |

≤1% |

≤1% |

|

|

efficiency |

≥95% |

≥95% |

|

|

power factor |

0.5 lagging to 0.7 leading |

0.5 lagging to 0.7 leading |

|

|

SCR bypass |

Yes |

Yes |

|

|

Display |

7-inch touch screen, providing parameter settings, power information, display, fault records, historical curves, etc |

7-inch touch screen, providing parameter settings, power information, display, fault records, historical curves, etc |

|

|

Noise |

≤65dB |

≤65dB |

|

|

Communication method |

4-way RS485 communication interface (supporting GPS/WIFI wireless communication), Ethernet interface, USB interface/span> |

4-way RS485 communication interface (supporting GPS/WIFI wireless communication), Ethernet interface, USB interface |

|

|

Protection function |

Overload, software/hardware overcurrent, power grid overvoltage/undervoltage, over temperature, frequency anomaly protection, etc |

Overload, software/hardware overcurrent, power grid overvoltage/undervoltage, over temperature, frequency anomaly protection, etc |

|

|

Heat dissipation method |

Forced air cooling |

Forced air cooling |

|

|

Incoming method |

Upper incoming and outgoing lines |

Upper incoming and outgoing lines |

|

|

Protection level |

IP20 |

IP20 |

|

5、Specification and model

|

Whole cabinet device model |

||||

|

Common models |

Rated power (kW) |

System voltage (V) |

Overall dimensions: Width * Depth * Height (mm) |

Cooling method |

|

STD AVC-0.4-30k-L |

30 |

400 |

600*400*1000 |

Forced air cooling |

|

STD AVC-0.4-45k-L |

45 |

400 |

600*400*1000 |

Forced air cooling |

|

STD AVC-0.4-60k-L |

60 |

400 |

750*550*1400 |

Forced air cooling |

|

STD AVC-0.4-90k-L |

90 |

400 |

750*550*1400 |

Forced air cooling |

|

STD AVC-0.4-120k-L |

120 |

400 |

900*700*1800 |

Forced air cooling |

|

STD AVC-0.4-150k-L |

150 |

400 |

900*700*1800 |

Forced air cooling |